Professor Chang’s research areas include application of synchrotron radiation, deformation behavior of metals and creep mechanism of metals. In the past decade, synchrotron radiation related technologies are some of most effective methods for engineering material characterization. Combined with different environment devices, many multi-objectives in situ experiments could be conducted effectively in the beamline. Professor Chang developed one customized in-situ testing system at Shanghai synchrotron radiation facility (SSRF) beamline BL12SW to conduct in situ observation of structural evolution of metallic materials during the deformation using high energy X-ray. Professor Chang also conducted in-situ creep test on T92 heat resistance steel by self-designed steam environment creep testing machine. The injected hydrogen which could facilitate dislocation movement presumably accelerated the creep rates and resulted in the premature failure of the specimens exposed in the steam environment.

-Project 1:“Fundamental Research Funds for the Central Universities”, Microstructure evolution of welds of third generation main pipeline materials during thermal aging, total fund 100000 RMB, 2021.01-2022.1

-Project 2:“National Natural Science Foundation of China”, “The lattice misfit of Co based superalloy during the heating process”, total fund 250000 RMB, 2012-2015

-Project 3:“Fundamental research funds for the central universities”, FRF-TP-12-165A, “Measurement of the lattice misfit of Co based superalloy using synchrotron radiation”, total fund 50000 RMB, 2012-2013

-Project 4:“China Postdoctoral Science Foundation”, 11175016, “The interface characterization of the Mg/Al laminated composite fabricated by accumulative roll bonding”, total fund 30000 RMB, 2012-2013

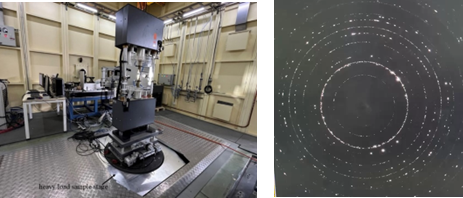

- One universal in-situ deformation testing system has been installed successfully at the beamline BL12SW of Shanghai synchrotron radiation facility. The in-situ testing system was designed to apply multiple functions including tensile/compression and the simultaneously rotation along the tensile axis, as well as the electric heating of the metallic specimen. Two electrical torsional actuators enable the ω-rotation of the specimen along the tensile axis without blocking the beam by the columns of the loading frame. Lattice strain partitioning, texture evolution and imaging experiments have been conducted successfully.

The customized in-situ testing system installed at Shanghai synchrotron radiation facility (SSRF) beamline BL12SW

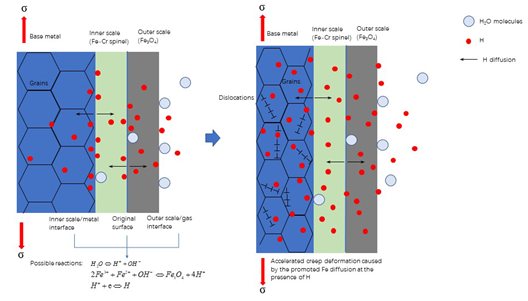

- One self-designed testing system was utilized to investigate the creep behavior of the T92 steel in water vapour environment. The presence of water vapour accelerated the minimum creep rate and reduced the creep plasticity of T92 steel in the humid air. The hydrogen introduced by the formation of oxidation scale during the creep tests in water vapour environment presumably promoted the diffusion of Fe atoms with the reduced activation energy and then accelerated the creep rates in present research.

The self-designed steam environment creep testing system

Illustration of the possible creep mechanism of the T92 steel in steam environment

Fujio Abe*, Hai Chang*, Weiwen Yan; Meiling Wang; Chenguang Shang; Yonghao Lu; Koichi Yagi; Xuechong Ren, Influence of hydrogen produced during steam oxidation on creep deformation and rupture ductility of Gr.92 steel, International Journal of Pressure Vessels and Piping, 2025, 214: 105410

Hai Chang, Weiwen Yan; Meiling Wang; Chenguang Shang; Yonghao Lu; Koichi Yagi; Xuechong Ren*, Effect of steam on the creep behavior of T92 steel at 650°C, International Journal of Pressure Vessels and Piping, 2023, 204: 104976

Hai Chang*, Chensheng Yang, Feifei Huang, Hongbo Zhang, Lei Wen, Wenchao Li, Yibo Ai, Ying JinϮ, Study of stress-corrosion cracking on 304 stainless steel by wedge opening loading method and acoustic emission technique, J Mater Eng Perform; Article in press, 2024, DOI: 10.1007/s11665-024-10427-4

Chang Hai, Hu Xiaoshi*, Du Junfeng, Tong Libo,Aging behavior of the extruded SiCp-reinforced AZ91 Mg alloy composite,Journal of Materials Research, 2019, 32 (2), 335-343.

CHANG Hai, XU Chao, HU Xiaoshi*, Microstructure evolution and mechanical properties of Mg/ZK60 laminated composite fabricated by accumulative roll-bonding, Acta Materiae Compositae Sinica, 2019, 36 (01), 178-185.

ZL 2023 2 0367987.5(CN 219694710 U);

ZL 2018 1 0195392.X(CN 108489891 B);

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026